Product Description

Lumley Tikka T3 / T3x Titanium and 7075-T76 alloy Trigger Guard Assembly for Factory Detachable Box Magazines

Finally - a high quality bottom metal replacement for the original plastic version at a very competitive price. Fully CNC-machined from a mix of high-grade titanium and aluminum alloys with absolutely no cheap 6000 series aluminum alloy used anywhere. The development of this bottom metal replaces the last chunk of plastic that comes with the factory rifle. This results in a very strong, lightweight and corrosion resistant product - providing the perfect bedding platform for your T3 or T3x rifle (bedding pillars and hex-head action screws included).

Features

- Very light - weighs under 3oz (83.5g)

- The body of DBM is machined from high grade 7075-T76 aluminum alloy

- The trigger guard is machined from aerospace Ti6Al4V titanium alloy

- The magazine release lever is machined from aerospace Ti6Al4V titanium alloy

- All other components are stainless steel (either 304 or 316 grades)

- Generally a 'drop-in' fit for most rifles (see conditions below in 'fitting guide')

- Accepts all T3/T3x magazines, not compatible with the CTR magazine.

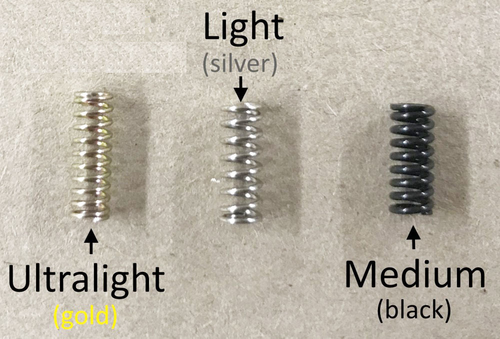

- Black color - PVD finished Ti parts, Milspec type 3 hard coat anodized body

- The trigger guard is fully replaceable and serviceable

- Includes bedding pillars and non-tapered hex head screws (both 316 stainless)

Fitting Guide

For bedding your T3 or T3x, (BEDDING GUIDE)

This DBM follows the factory inlet 100% and does not require any modification to the stock aside from drilling the action screw holes out to 10mm to fit the pillars (if applicable).

In most cases this will be a 'drop in' or 'push-in' fit for factory timber or laminate stocks - however please note factory tolerances vary which can cause fitment issues for some rifles

The factory synthetic stocks have very poor tolerances due to shrinkage after molding. When fitted to these stocks, the DBM in most cases will need to be gently tapped into the inlet (cover with a soft towel and use a nylon tipped hammer)

Our magazine release lever is designed to lock the magazines up tight. The plastic original is typically shorter by up to 0.5mm to 0.75mm than it needs to be (varies based on degree of wear / distortion from use). This sloppy tolerance is partly why the tension spring is there to take up the slack. Due to differences between individual magazines, the top of our lever may need to be shortened between 0.5mm to 0.75mm for your particular rifle and magazine(s). This is quickly and easily done by just 4 or 5 firm swipes with a metal file (with lever removed from DBM and secured in a vise).

Our DBM is very rigid - whereas the plastic original is not. For this reason the factory tension spring is rigid (0.50mm thick) and excessively angled pushing the magazine forwards to counter the flex of the factory plastic parts. This causes problems for some customers with the magazine not clipping into our DBM unless it is pulled backwards against this tension spring when inserted. To correct this spring tension, remove it from the trigger housing (5mm hex key required) and reduce the angle closest to the screw hole to 90 degrees by bending it whilst clamped in a vise.

Don't rely on your stock having the correct spacing between the action and DBM at either the front or rear action screws - use our pillars or measure the tangs (front: 22.7mm / 0.8937" and rear: 33.02mm / 1.3" ). Test fit the DBM to the action first using only the pillars and action screws (no stock) to check magazine function.

The previous three steps account for virtually 100% of fitment issues. It doesn't take long to fit this DBM and have it functioning reliably.

Product Videos

Custom Field

Product Reviews

2 Reviews Hide Reviews Show Reviews

-

Trigger guard

Very pleased with this trigger guard, it fits perfect.

-

The trigger guard looks great and fits perfectely.

Great communication and fast service. Would deal with them again without any concerns.